VR-VIRTUAL REALITY

DIGITAL TECHNOLOGIES TO EMPROVE SAFETY

where did we start from?

Poweren® has been charged to design an entire secondary solid fuel production plant (CSS), fuel processed from municipal non-hazardous waste and special non-hazardous waste whose treatment and handling can be managed only on authorized (D.lgs. n. 152/2006 proc. ord. Parte Seconda, Tit. III Bis – AIA) and certified plants (UNI EN 15358). Besides developing the layout, the executive drawings of carpentry structures, machinery and suction lines, we have been asked to guarantee a plant strictly in compliance with safety laws, since the design. We had to consider every single aspect that could lead to any danger and forsee actions to prevent it: heights to respect, ducts, wires, beams, gutters pits, columns, narrow walking surfaces or maintenance rooms, lack or deficiency of natural light, access or escape routes. .

What has been the solution?

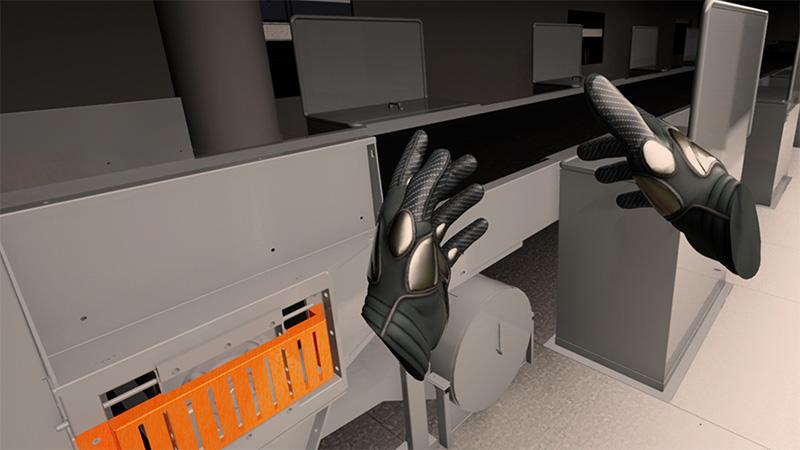

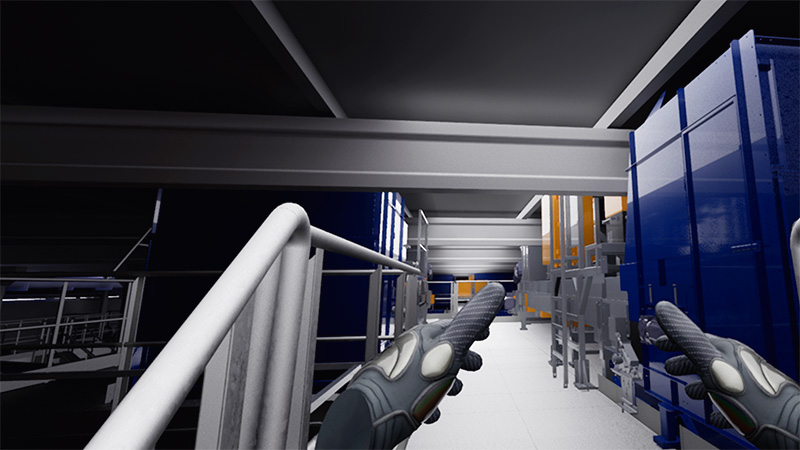

Interacting within the virtual environment by using devices like headset and controllers allowed us to validate the project and train the staff about the correct use of the plant. Virtual reality enabled us to test the design choices we adopted in order to respect the requirement set by safety and security laws. We checked routes, rooms and trouble spots. We simulated various scenarios and tested emergency situations evaluating effects and main issues. We verified the impact of each single possible option. Moreover, Virtual reality allowed staff training thanks to the possibility to test emergency situations in a safe environment and gaining of necessary experience to face safely the eventual crisis. Staff members also previously instructed on the correct use of the plant because of training on safety and maintenance procedures.