ENERGY RECOVERY FROM ROTARY KILN FUMES

WHERE DID WE START FROM?

The customer contacting us intends to build a new energy production plant from the heat recovery of the exhaust fumes of his (own) rotary kiln. The fumes in question still have a fair amount of energy and energy content.

We are therefore asked to carry out a study to determine the best solution for these fumes to be returned to circulation and contribute to the energy requirements in terms of steam and hot water during various operating conditions.

It must be borne in mind that the production and consumption of steam and water during the production cycle of the steel mill is variable and reaches its peak during the degassing phase, a phase in which superheated steam at 250°C 14 bar (a) and hot water at a temperature of 65°C – 95°C must be guaranteed.

WHAT HAS BEEN THE SOLUTION?

By analysing the basic characteristics of the thermal cycle and its constituent components, we learnt that the steam consumption trend over time has a certain base value and a peak value, and that the latter occurs when the delicate degassing step is required to remove residual impurities.

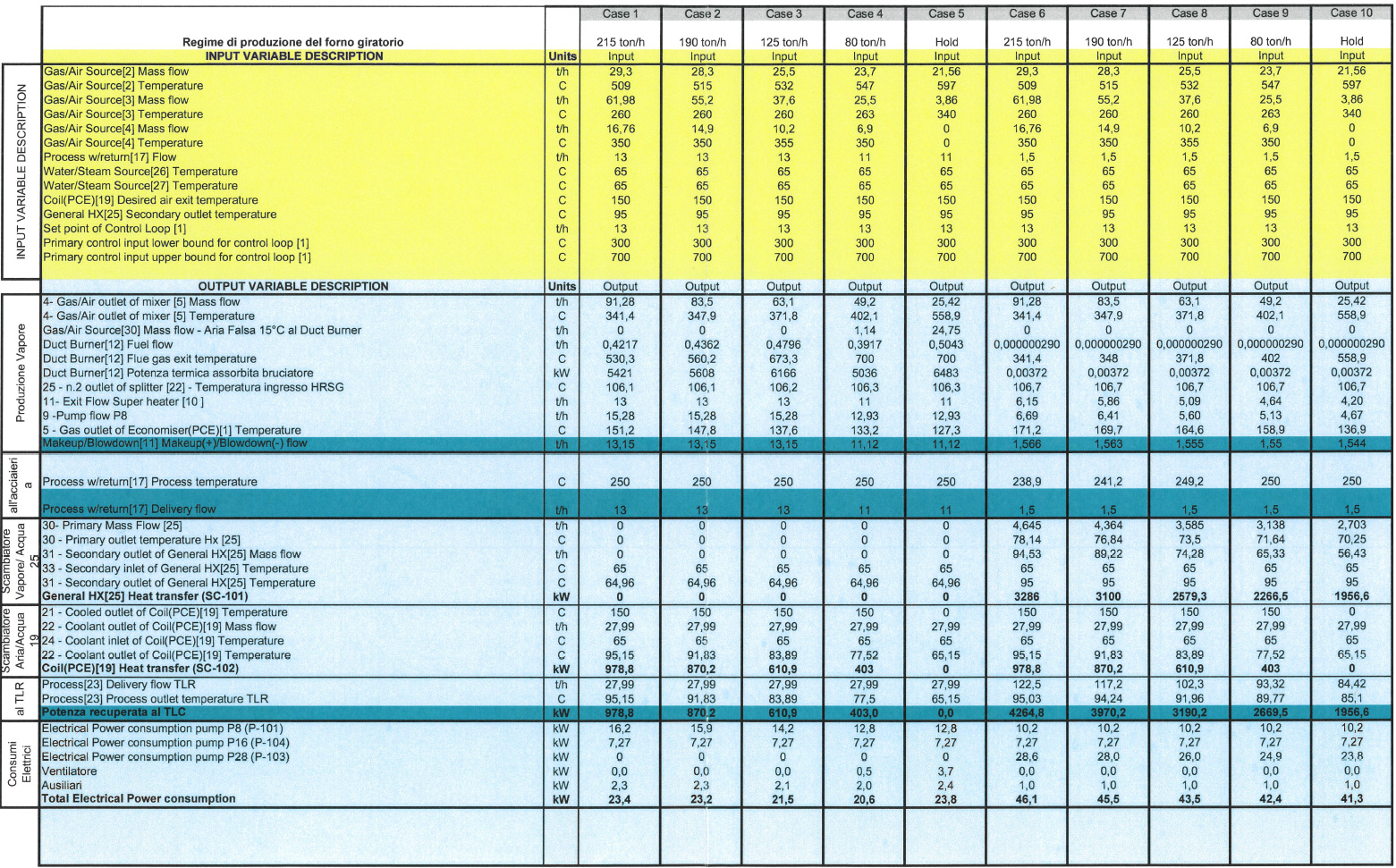

We have simulated operation at maximum and minimum steam demand conditions in order to determine the sizing of the production plant and that of the steam/water exchanger, respectively, which would allow flue gas recovery and energy savings.

The simulation takes into account all operating conditions of the furnace. For each of them, we have highlighted the steam production and the power recovered in the form of hot water, both in maximum and minimum demand for superheated steam.

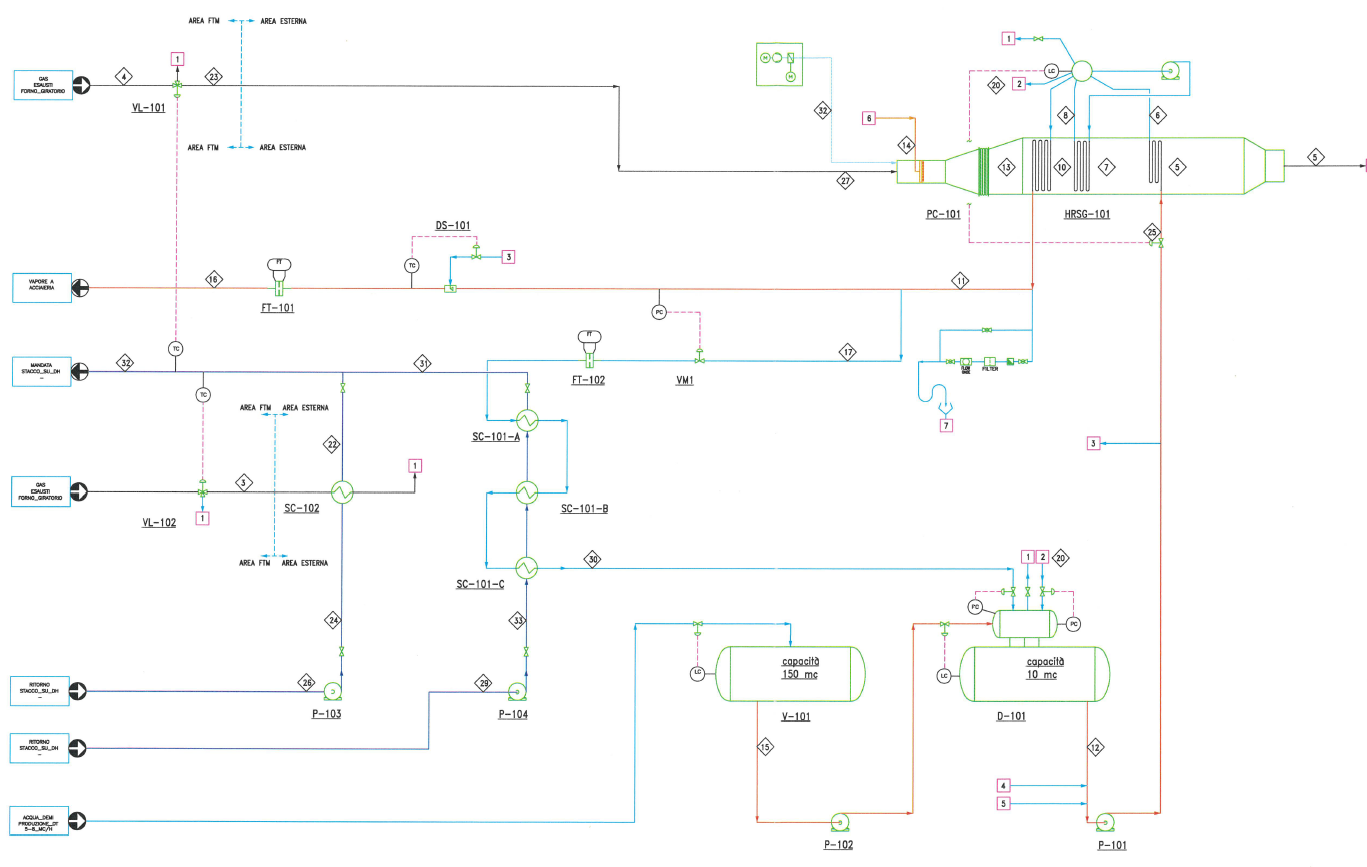

The analysis leads to the identification of the most suitable system, which specifically envisages:

- by-pass on the main chimney and pre-heating chimney, to intercept the exhaust gases at the outlet and divert them towards the air flue gas exchanger on the pre-heating chimney;

- recovery boiler for the production of superheated steam, crossed by the combustion fumes coming out of the main chimney;

- modulating air vein burner fuelled with natural gas from the mains coupled with an additional air blower that comes into operation if the steam produced is not sufficient to meet the entire demand during the degassing phase;

- steam/water exchanger for the production of hot water to be sent to the district heating system via a pump.

WHAT HAS BEEN THE OUTCOME?

Steam production by the suggested system (recovery boiler + burner in the vein) satisfies the required degassing requirements under all conditions. The recovered thermal energy in the form of hot water is always usable. Emergency conditions are verified by the presence of by-passes in the respective chimneys, which divert the flow of hot fumes to the atmosphere in the event of a malfunction detected in each recovery system.

The technical feasibility study made it possible to identify the best system to meet the client’s heat recovery needs while ensuring that the new system does not affect the normal continuous operation of the rotary kiln, even in the event of any stoppages for maintenance and/or breakdowns.