LINEA DI TRITURAZIONE: CONSULENZA ANALISI RISCHI

WHERE DID WE START FROM?

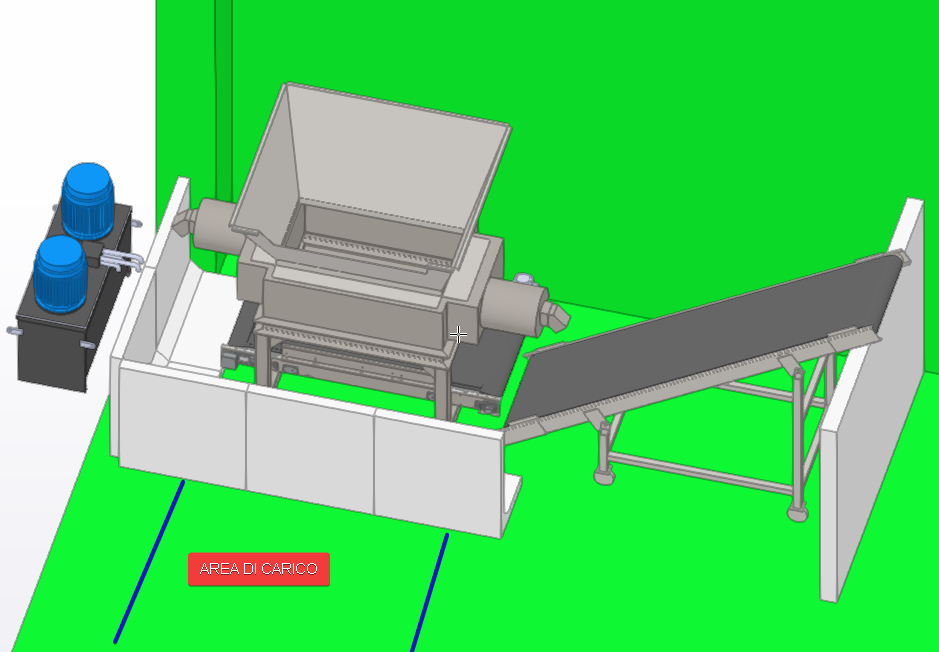

When the shredding line machines were relocated within an existing plastics processing plant, we drew up the relevant assessment report.

Whenever a plant or part of a plant is modified, increased and relocated, a new Risk Assessment must be carried out, verifying which have been eliminated or reduced and which, if any, have been introduced or increased.

WHAT HAS BEEN THE SOLUTION?

To carry out the assessment, our appointee carries out an on-site visit to the plant to verify the new conditions resulting from the relocation of the machine.

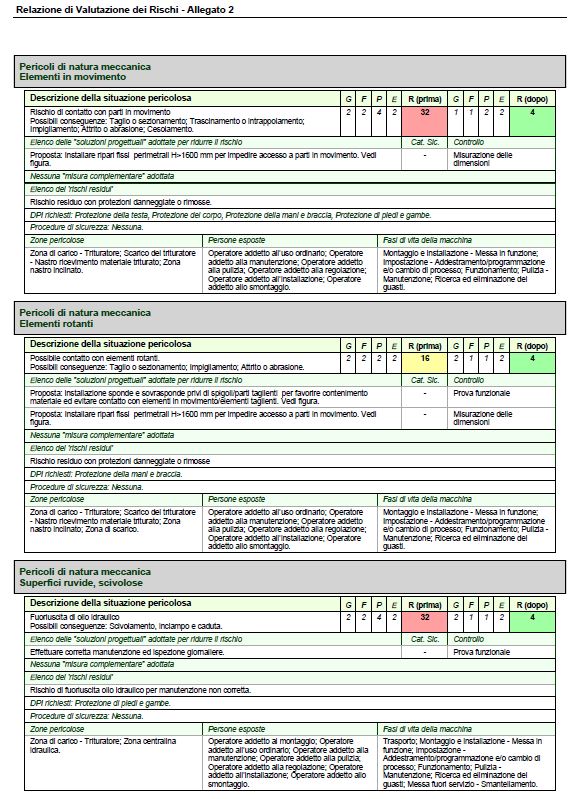

Based on the information gathered, we create a generic layout, define the machine’s operating limits and compile a list of hazards. The hazards are identified using dedicated software that classifies them into logical units (mechanical, thermal, electrical, chemical, etc.) according to EN ISO 12100, Appendix B.

Each unit is analysed in detail, considering all aspects that may affect safety. For each risk, we estimate an index representing its severity and probability. We identify for each risk:

- the source of the hazard;

- the possible consequences;

- the most effective technical solutions to eliminate or minimise it;

- any complementary measures to be taken.

Eliminating the hazard is always the priority. When this is not possible, action is taken by minimising the probability and severity of the damage.

Knowledge of the causes and elements of risk allows us to define the most suitable protective measures. The application of these measures determines the final risk index, which is listed in the Assessment document.

Finally, the residual risks are listed, i.e. the risks that remain after all the planned prevention and protection measures have been taken.

WHAT HAS BEEN THE OUTCOME?

We have considered all operating conditions and possibilities for action. Hazards have been eliminated or risks reduced to the lowest possible level. The hazards generated by the protective measures taken have also been considered.

The end operators are made aware of and warned about the residual risks and the safe use of the machines.

By entrusting us with the drafting of the Risk Assessment and Analysis, the client is assured of a complete document containing all the proposed design-integrated protective measures, complementary protections and information for use to be adopted in order to comply with the safety and health protection requirements laid down by the regulations in force.