STRUCTURAL CONFORMITY & SUITABILITY FOR USE CARPENTRY STRUCTURES

WHERE DID WE START FROM?

Customers turn to Poweren not only for mere design but also for engineering consultancy.

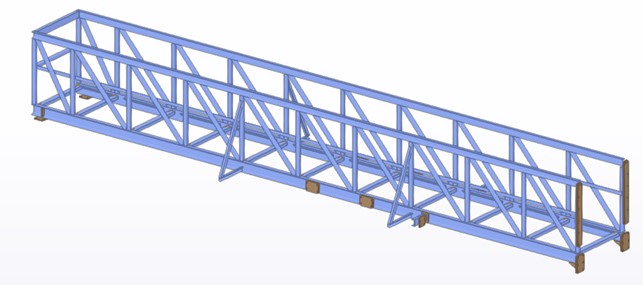

Recently, for example, we carried out a study to assess the structural compliance and suitability for use of certain structures: two steel footbridges used for inspection and maintenance of two sludge separation tanks for water treatment.

The gangways were fixed to the top of the tanks themselves and acted as load-bearing elements to support the central body to which a motor for moving the water was attached.

WHAT HAS BEEN THE SOLUTION?

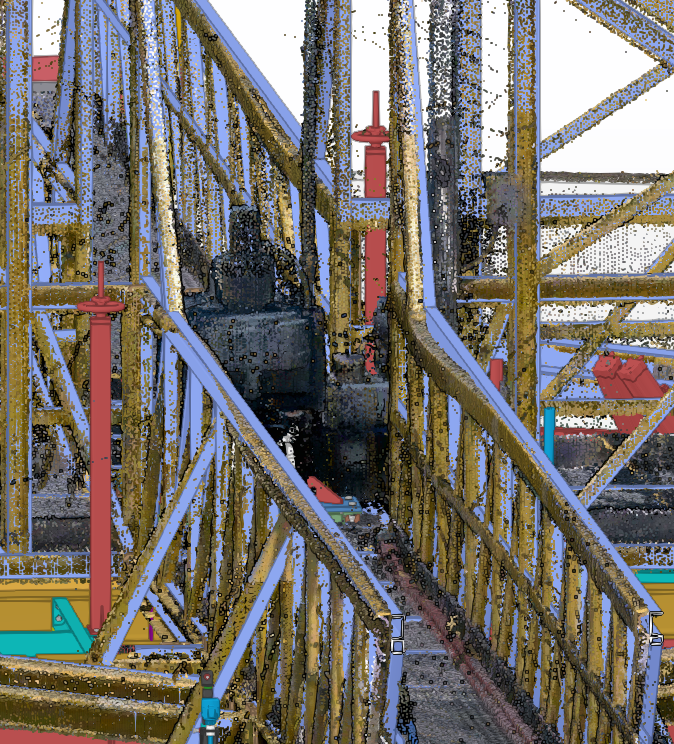

We carried out an inspection to acquire the data necessary to define the point cloud and the “state of affairs” of the structures and found that there was considerable deformation of the upper handrail. The deformation was visible even to the naked eye, but to understand how important it was and how it affected functionality, we had to test its elasticity.

With 3D scanning, we recorded data both with a full tank and with the underlying motor running, and with an empty tank. In the latter case, the tank had been emptied and the motor dismantled so that the gangway had no added loads other than its own weight and possibly that of the operator.

Working within the data sharing environment (CDE), by superimposing the point cloud on the 3D mathematical calculation model, we evaluated and quantified the deformation state of the structure.

In the light of the structural analysis, it was found that the deformations had entered the plastic field (no longer only mechanical) and had therefore become permanent. The footbridges could no longer be considered safe.

WHAT HAS BEEN THE OUTCOME?

Having gathered all the information, we presented the client with a declaration stating that the footbridges no longer met the mechanical strength and stability characteristics required by building regulations for structural use applying the original design loads.

Thanks to our study, the client was put in a position to make informed decisions on the management, maintenance/replacement of the gangways to prevent hazards to operators and take action to avoid risks.

WHAT TECNOLOGY ARE WE USING?

The technology that gave us the opportunity to solve the critical issues of this project is undoubtedly the application of our LAMAPIM method and specifically the use of the 3D Laser Scanner and related point post-processing software, the CDE platform for data sharing and dedicated structural analysis & FEM software.